Release time: Apr. 04, 2025

A track roller is a basic load-bearing part placed at the very bottom of a tracked vehicle's undercarriage. It directly takes the weight of the equipment and gives stability when the tracks move on various terrains. Track rollers distribute the load, reduce friction, and thus the machine can work smoothly and efficiently.

Track rollers are usually made of high-strength steel and are built to bear the weight and absorb shock and abrasion. The life of the track rollers can be extended by faithful lubrication, and regular maintenance is crucial.

A carrier roller, roller is instead found at the top of the undercarriage and mainly helps to carry the upper part of the track chain. The load is not directly supported by carrier rollers, unlike track rollers. Their task is to guide the track and prevent it from wandering, as a result, the track structure lasts longer.

Track rollers serve as a bottom part of the undercarriage and are responsible for direct contact with the track shoes to move the machine. Despite the fact that the heavy-duty track subject the track rollers to an enormous amount of stress, they need to be looked after to function properly. The first part of the statement is the focus in the first sentence of the original text.

1. Position on the Undercarriage: The underside of the carrier machines is where the track rollers move, while carrier rollers are on the upper side.

2. Load-Bearing Role: The force is provided by the track rollers as they bear the weight of the whole machine, whereas the task of the carrier rollers is to support the track chain.

3. Wear and Tear: Track rollers which are at ground level and move constantly are subject to a greater amount of wear and tear than carrier rollers.

4. Functionality: Track rollers give stability and traction, while carrier rollers keep the track from sagging and also prevent it\'s misalignment in the process.

Selecting a reputable carrier roller manufacturer is crucial to ensuring high-quality and durable components for construction and mining equipment. A reliable manufacturer uses top-grade materials, advanced engineering, and stringent quality control processes to deliver products that withstand harsh working conditions. Investing in superior rollers can enhance equipment performance, minimize downtime, and reduce maintenance costs.

Working directly with a carrier roller factory provides several advantages:

Customization Options: Factories can produce rollers tailored to specific machine models and operational needs.

Cost Savings: Buying directly from a factory eliminates middlemen, reducing costs while maintaining product quality.

Consistent Supply: A dedicated factory ensures steady availability of rollers, preventing project delays due to supply shortages.

Both track rollers and carrier rollers play essential roles in the performance and longevity of tracked machinery. While track rollers support the equipment’s weight and provide traction, carrier rollers help maintain track alignment and reduce wear. Choosing high-quality rollers from a reputable carrier roller manufacturer or carrier roller factory is vital to keeping construction and mining operations running smoothly. Regular inspection and maintenance of these components can further enhance the efficiency and durability of the machinery.

Protection Type Round Sling

Protection Type Round Sling

Elevator Link

Elevator Link

JQ550 Bridge Erecting Crane

JQ550 Bridge Erecting Crane

Lashing Belt Material

Lashing Belt Material

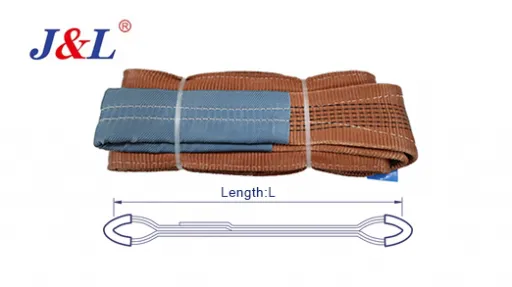

Heavy Eye Webbing Sling W02-12 | Webbing Slings by J&L

Heavy Eye Webbing Sling W02-12 | Webbing Slings by J&L

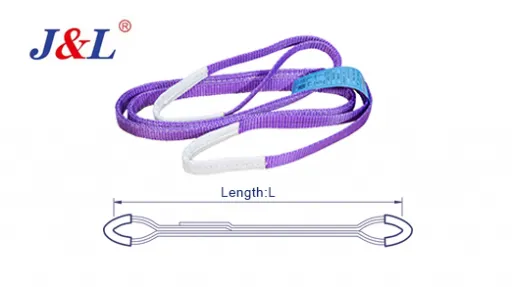

W01-6 Eye Type Polyester Webbing Sling

W01-6 Eye Type Polyester Webbing Sling

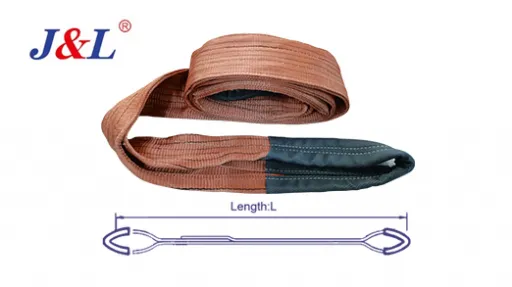

Heavy Eye Webbing Sling W02-02 | Webbing Slings by J&L

Heavy Eye Webbing Sling W02-02 | Webbing Slings by J&L

Heavy Eye Webbing Sling W02-04 | Webbing Slings by J&L

Heavy Eye Webbing Sling W02-04 | Webbing Slings by J&L

Grommet Sling

Grommet Sling

Steel Coil Lifting Tool (“C” type)

Steel Coil Lifting Tool (“C” type)