Release time: Apr. 30, 2024

Welcome to our comprehensive guide on webbing slings, a versatile and essential tool used in various industries. In this article, we will explore the different aspects of webbing slings, including their uses, benefits, variations, and safety considerations. Whether you are a professional or simply curious about this equipment, our goal is to provide you with a wealth of information that will help you better understand webbing slings and their significance in lifting and securing heavy loads.

Webbing slings, also known as lifting slings, are flexible and durable straps made from high-quality synthetic materials. These slings are designed to facilitate the lifting, hoisting, and securing of heavy objects, making them indispensable in industries such as construction, manufacturing, logistics, and more. The primary purpose of webbing slings is to provide a reliable and safe means of transporting loads by distributing the weight evenly across the surface area of the sling.

1. Flat Eye Webbing Slings

Flat eye webbing slings feature flat loops on both ends, making them versatile and easy to use. They are suitable for a wide range of applications and offer excellent load stability. These slings are ideal for lifting irregularly shaped objects or those with fragile surfaces that require extra care.

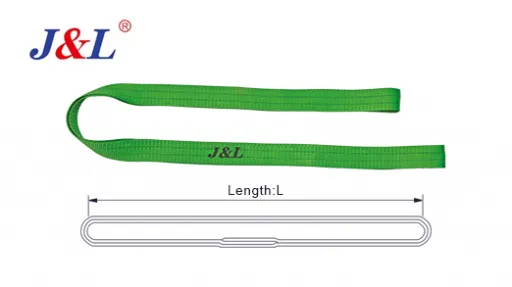

2. Endless Webbing Slings

Endless webbing slings, as the name suggests, form a continuous loop without any seams or joints. This type of sling is highly flexible, making it convenient for various lifting operations. It allows for multi-directional lifting, which is particularly useful when maneuvering loads in tight spaces.

3. Round Webbing Slings

Round webbing slings, also referred to as endless round slings consist of a continuous loop with a protective outer sleeve. These slings are exceptionally versatile and gentle on delicate surfaces. The round shape offers excellent load-bearing capacity and makes it easier to handle loads with uneven weight distribution.

4. Triangle Webbing Slings

Triangle webbing slings are designed with a triangular shape, featuring three legs that converge into a single attachment point. This design provides superior stability and load control. Triangle slings are particularly effective for lifting cylindrical objects, such as pipes or barrels.

Webbing slings find applications in various industries where heavy lifting is required. Some common uses include:

1. Construction Industry

In the construction sector, webbing slings play a vital role in lifting heavy materials such as steel beams, concrete blocks, and machinery. Their versatility and strength make them an indispensable tool for construction projects of all sizes.

2. Manufacturing and Warehousing

Manufacturing facilities and warehouses rely on webbing slings to move and transport heavy equipment, machinery parts, and finished products. These slings provide a safe and efficient means of handling goods during the production and distribution processes.

3. Shipping and Logistics

The shipping and logistics industry heavily depends on webbing slings for loading and unloading cargo from trucks, ships, and airplanes. Webbing slings ensure the secure transportation of goods, reducing the risk of damage and accidents.

4. Automotive and Transportation

In the automotive sector, webbing slings are used for lifting and securing vehicles during repairs, maintenance, and recovery operations. They provide stability and prevent potential damage to the vehicle or surrounding objects.

Webbing slings offer numerous advantages over alternative lifting methods. Let's explore some of the key benefits:

1. Strength and Durability

Webbing slings are manufactured using high-strength synthetic materials that can withstand heavy loads. They are designed to be resistant to abrasion, UV radiation, and chemicals, ensuring their longevity and reliability.

2. Flexibility and Adaptability

The flexibility of webbing slings allows them to conform to the shape of the load, ensuring optimal contact and load distribution. Their adaptability makes them suitable for lifting objects of various sizes, shapes, and weights.

3. Lightweight and Portable

Compared to traditional lifting equipment, webbing slings are lightweight and easy to transport. Their compact design makes them convenient to store and carry, enhancing efficiency and saving valuable space.

4. Cost-Effective

Webbing slings are a cost-effective solution for lifting operations. Their durability and long lifespan reduce the need for frequent replacements, resulting in significant cost savings over time.

While webbing slings are designed to enhance safety during lifting operations, it is crucial to adhere to certain safety guidelines to prevent accidents or injuries. Here are some key safety considerations:

1. Regular Inspections

Inspect webbing slings regularly for signs of wear, damage, or deformation. Replace any slings that show signs of wear and tear to avoid potential failure during lifting operations.

2. Weight Limits and Working Load Limits (WLL)

Always ensure that the webbing sling's capacity matches or exceeds the weight of the load you intend to lift. Exceeding the working load limit can compromise the sling's integrity and lead to accidents.

3. Proper Handling and Storage

Handle webbing slings with care, avoiding sharp edges or abrasive surfaces that could damage the material. Store slings in a clean and dry environment to prevent degradation and maintain their effectiveness.

4. Training and Certification

Ensure that personnel involved in lifting operations receive proper training and certification to handle webbing slings safely. Knowledge of proper lifting techniques and safety protocols is essential to minimize risks.

In conclusion, webbing slings are an indispensable tool for lifting and securing heavy loads in various industries. Their versatility, strength, and cost-effectiveness make them a preferred choice for professionals seeking reliable lifting solutions. By understanding the different types of webbing slings, their uses, benefits, and safety considerations, you can optimize your lifting operations and ensure the safety of your personnel and equipment.

Remember, when utilizing webbing slings, always prioritize safety, adhere to manufacturer guidelines, and perform regular inspections to maintain their effectiveness and prevent accidents. We are a webbing sling supplier. If you are interested in our products, please contact us now!

Steel Coil Lifting Tool (“C” type)

Steel Coil Lifting Tool (“C” type)

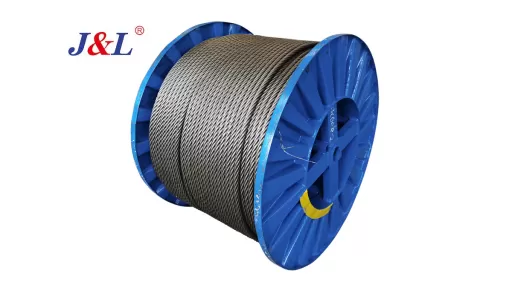

Galvanized Steel Wire Rope

Galvanized Steel Wire Rope

Ratchet Strap With Hook

Ratchet Strap With Hook

Mooring Rope

Mooring Rope

Endless Type Webbing Sling W03-02 | Webbing Slings by Juli Sling

Endless Type Webbing Sling W03-02 | Webbing Slings by Juli Sling

Hook and Ring

Hook and Ring

6×19S+IWR Round Strand Steel Wire Rope

6×19S+IWR Round Strand Steel Wire Rope

Monofilament Polypropylene Mooring Rope

Monofilament Polypropylene Mooring Rope