Release time: Sep. 04, 2025

In heavy-duty industries where safety and efficiency go hand in hand, choosing the right partner for lifting and rigging solutions is critical. Among the options available, steel wire rope suppliers stand out as vital partners for construction, mining, shipping, and manufacturing. The wrong supplier could lead to premature wear, equipment failure, and costly downtime. The right one, like Juli Sling, ensures dependable performance, compliance with international standards, and peace of mind.

Steel wire rope is widely used in cranes, hoists, winches, elevators, and marine applications. Its combination of tensile strength, flexibility, and resistance to abrasion makes it indispensable. However, not all ropes are created equal. The material quality, strand construction, and supplier expertise directly affect durability, safety, and cost-efficiency.

When evaluating steel wire rope suppliers, businesses should consider the following:

Quality Standards: Ensure suppliers comply with ISO, CE, or other international certifications for safety and performance.

Material Reliability: High-grade steel with uniform tensile strength prevents early fatigue and breakage.

Range of Products: From galvanized and stainless-steel ropes to specialized constructions for elevators or cranes, a wide product portfolio indicates expertise.

Customization Options: Suppliers should provide tailored solutions, including rope diameter, strand patterns, coatings, and terminations.

Testing and Traceability: Look for suppliers offering load testing, fatigue tests, and traceable manufacturing records.

After-Sales Support: A reliable supplier provides not only products but also technical advice, training, and replacement availability.

Construction: Tower cranes, lifts, and scaffolding rely heavily on robust ropes.

Shipping and Marine: Ropes resistant to corrosion and saltwater are essential for mooring and cargo handling.

Mining: Heavy-duty ropes withstand abrasive conditions in hoisting and dragline operations.

Manufacturing: Used in machinery, elevators, and automated handling systems.

As one of the leading steel wire rope suppliers, Juli Sling delivers products designed for demanding global industries:

Proven Reliability: Decades of experience supplying steel wire ropes across construction, mining, shipping, and energy sectors.

Advanced Manufacturing: State-of-the-art technology ensures uniform tensile strength, flexibility, and long service life.

Comprehensive Range: From compacted strands to galvanized and stainless options, meeting diverse industrial needs.

Customized Solutions: Tailored diameters, coatings, and terminations adapted to specific applications.

Strict Quality Control: Every rope undergoes rigorous testing to meet or exceed international standards.

Global Support: Technical assistance, safety guidance, and efficient logistics to serve clients worldwide.

Choosing a supplier is about more than price—it’s about safety, longevity, and trust. Working with experienced steel wire rope suppliers like Juli Sling ensures operational stability, reduces risk, and contributes to sustainable productivity. In industries where every lift matters, reliability is non-negotiable.

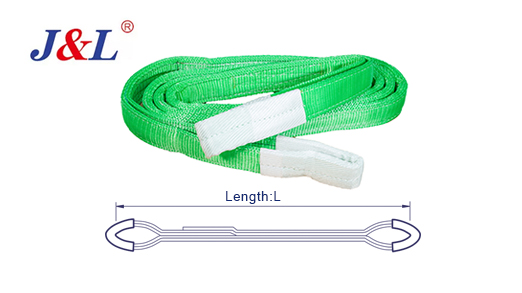

Heavy Eye Webbing Sling W02-04 | Webbing Slings by J&L

Heavy Eye Webbing Sling W02-04 | Webbing Slings by J&L

Steel Coil Lifting Tool (“C” type)

Steel Coil Lifting Tool (“C” type)

Vertical Steel Coil Lifting Clamp (Endless Wire rope sling type)

Vertical Steel Coil Lifting Clamp (Endless Wire rope sling type)

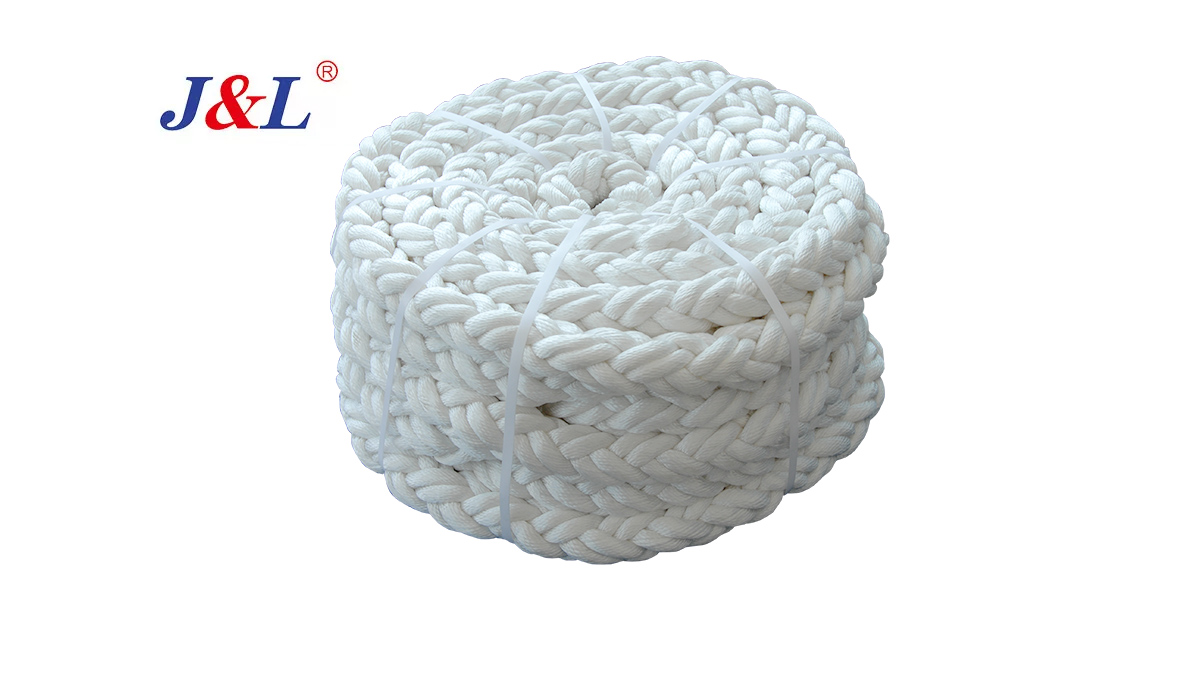

Polyester Mooring Rope

Polyester Mooring Rope

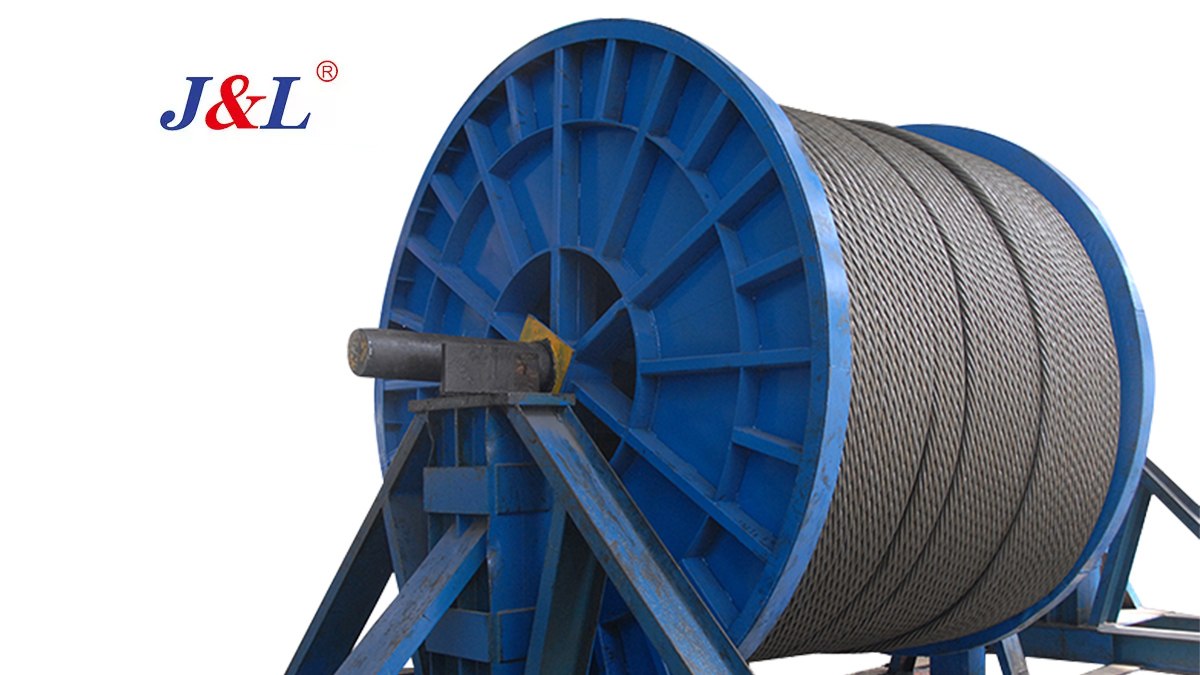

6×19S+IWR Round Strand Steel Wire Rope

6×19S+IWR Round Strand Steel Wire Rope

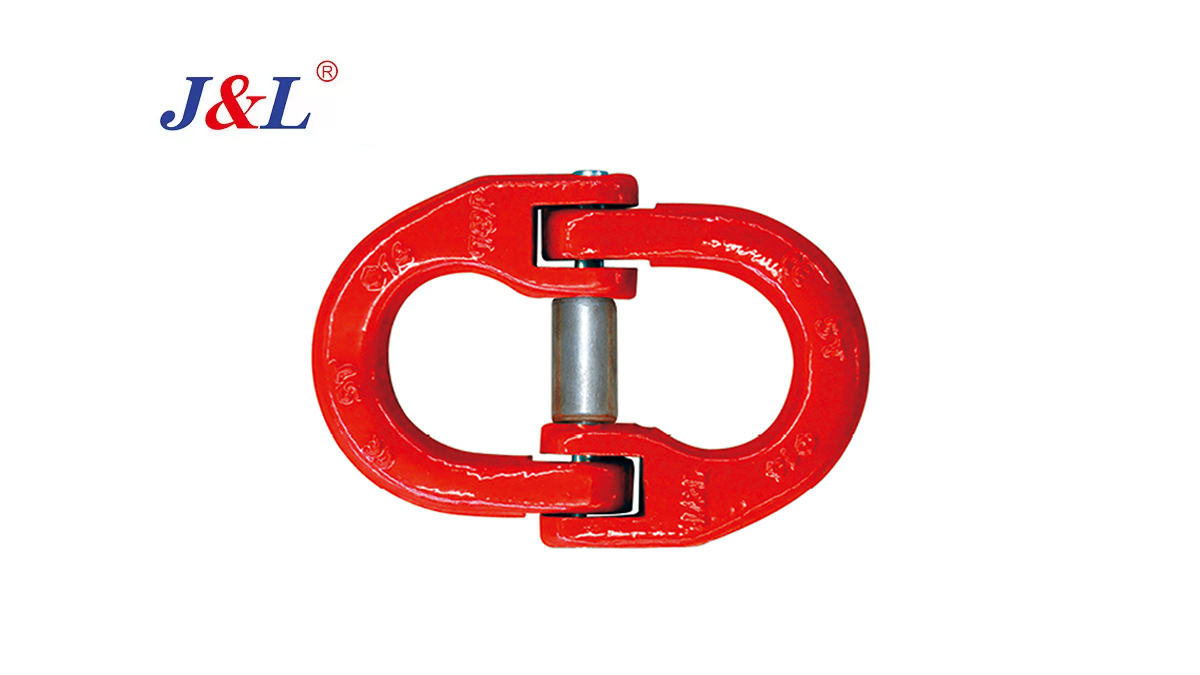

G80, G63 Connecting Link

G80, G63 Connecting Link

Monofilament Polypropylene Mooring Rope

Monofilament Polypropylene Mooring Rope

Endless Round Sling

Endless Round Sling

Ratchet Strap With Cam Buckle

Ratchet Strap With Cam Buckle