Release time: Jun. 04, 2025

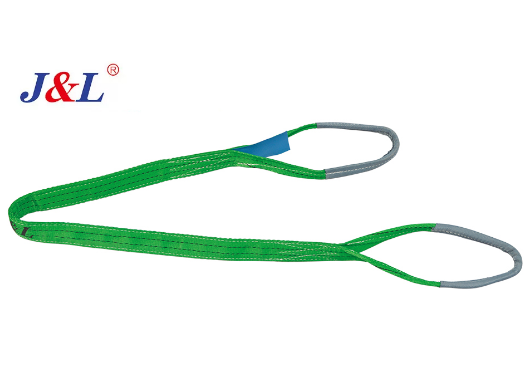

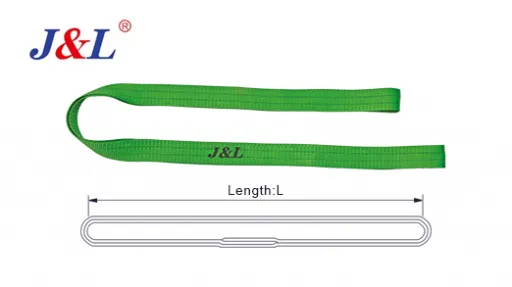

Safe and efficient heavy load lifting is mainly the equipment design issue as it plays a crucial role. The Heavy Eye Webbing Sling is among the various lifting solutions, which is unique in strength and flexibility. Most importantly, it is always interesting to most users to find out why the body is being -pulled two-ply while the eyes are generally made in one ply. Below, we will dissect the reasons for the choice of this design and its implications for safety and performance.

Webbing Slings are hefty products made of polyester or nylon, used for hoisting, towing, and other heavy lifting operations. The structure of a webbing sling mainly consists of the sling body and the eyes.

The main reasons to use the two-ply fabric are as follows:

When it is doubled, the load-bearing capacity of the sling increases significantly. The material is doubled and the force required by the sling is much stronger.

Equal sharing of the load: The two-ply webbing allows the weight of the load to be spread out more evenly to all parts of the sling. The stress on any one point, thus, will be less, and the probability of failure during lifting will be reduced.

Besides, the increased raw material assists the webbing in being more resistant to cutting and wearing. The slings used creating a rough environment might be subjected to sharp edges or rough surfaces. This is why the webbing construction has the second ply. The second ply will provide them with better cut and abrasion.

However, the eyes of the webbing sling are often made in one ply. There are multiple explanations of why this is done:

Flexibility: A single layer can flex freely and so it is easier to attach it to the hooks, shackles, or lifting hardware.

Reduced Bulk: The eyes must be of lying tight inside lifting devices. The a-ply one can reduce most of the bulk, and hence, you can get the sling threaded through the lifting devices without the addition of weight or extra parts.

Despite being one-ply, the eyes come with reinforcements to make sure the load they carry is not tearing or changing in shape. It is quite helpful that J&L uses good stitching and design in the eyes to achieve strength practical to lifting safely.

One of the main factors of your operation is choosing the most appropriate sling. These factors have to be considered:

1. Load Capacity

Make it a point that the heavy duty webbing sling you are going to choose will be able to withstand the weight of the loads that you want to lift.

The J&L Heavy Eye Webbing Sling is indeed one of the types of heavy-duty slings that have a load capacity of up to 20,000 kg, which means it is applicable for many types of heavy lifting operations.

2. Safety Factor

A large variety of webbing sling safety ratios is found in the market, ranging from 5:1 to 7:1. With a higher safety factor, the webbing sling is safer for use while doing lifting.

3. Material Quality

The materials used in the sling are a major factor in its performance. For the J&L slings, an advantage is that they are constructed of first-class polyester and nylon materials, which in turn guarantees to remain durable and wear-, UV-, and heat-resistant.

4. Customization Options

One of the essential things in dealing with lifting tasks is customization. J&L provides different lengths, different colors, and safety ratios, so that through these features, you can design the sling in the way you want for your specific applications.

Heavy Eye Webbing Slings are very flexible and can be used in a wide range of industries, some examples of which are:

Construction: Lifting and transporting mud concrete pipes, steel beams, and other machinery.

Manufacturing: Shifting the equipment and tools, mostly the biggest ones, across the factory.

Logistics: Packing and loading goods in transit and hoisting easily breakable stuff such as glass and marble.

Understanding the design differences between the two-ply body and one-ply eyes of webbing slings is essential for making informed choices in lifting equipment. The two-ply body enhances strength and durability, while the one-ply eyes provide flexibility and ease of use.

When choosing a webbing sling manufacturer, consider the quality, customization options, and safety features they offer. If you're looking for a dependable Eye Type Webbing Sling, explore J&L's range today. Our commitment to quality and safety makes us a trusted partner in your lifting operations. Contact us to learn more about our products!

Spliced Steel Wire Rope Sling

Spliced Steel Wire Rope Sling

JQ550 Bridge Erecting Crane

JQ550 Bridge Erecting Crane

High Tensile Endless Round Sling

High Tensile Endless Round Sling

High Tension Round Link Chain For Mining

High Tension Round Link Chain For Mining

Round Sling

Round Sling

W01-10 Eye Type Polyester Webbing Sling

W01-10 Eye Type Polyester Webbing Sling

Fireproof Eye Round Sling

Fireproof Eye Round Sling

Master Link Assembly

Master Link Assembly

Endless Type Webbing Sling

Endless Type Webbing Sling

Endless Type Webbing Sling W03-02 | Webbing Slings by Juli Sling

Endless Type Webbing Sling W03-02 | Webbing Slings by Juli Sling