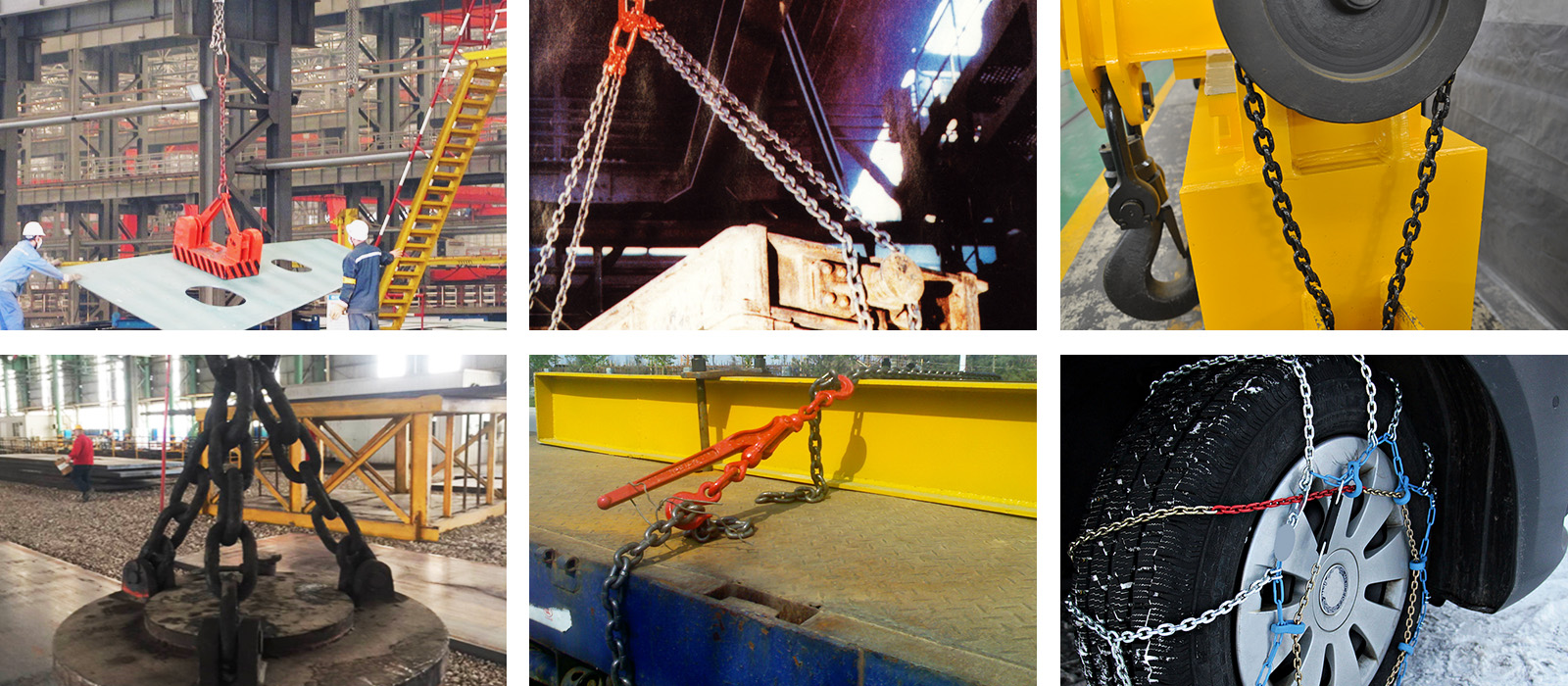

High-tensile lifting chain, high-tensile chain sling, round link chain and steel compact chain for scraper conveyor and auxiliary part for mine chain. The chain adopts high-quality special steel material from the domestic and foreign market

Description:

1. Application area: Mine scraper conveyor, scraper loader, plow and other equipment.

2. Quality grade: B, C

3. Marks: Quality grade mark, such as "JLB/JLC".

4. Production range is Ф18-Ф48mm.

5. Standards: Produced in accordance with the standard of GB/T12718-2009.

6. Certifications: Mining chain obtained MA certificate. Lifting chain obtained CE certificate

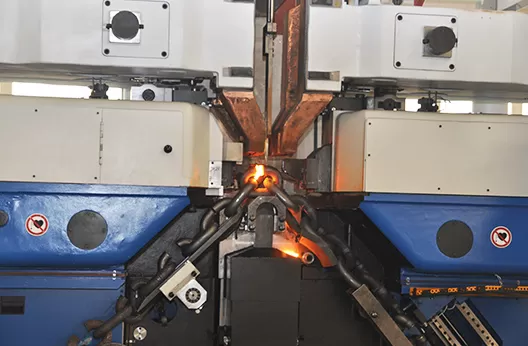

7. Equipment: Chain factory has chain making machine, flash butt welder, stretcher from WAFIOS (German) and SPECTROMAXx brand metallurgical analysis spectrograph.With the expansion of the market share in recent years, the factory has built 17 chain production lines, 3 chain sling assembly lines and 2 ring welding lines.

Main Features:

The advantage of our chains is wear-resisting, high temperature resistance, corrosion resistance, corrosion resistance, ductility, low stress, won't elongation, Mining chain obtained MA certificate. Lifting chain obtained CEcertificate and participated in the compose of GB/T24816 "Short link chain and hoists lifting chainwith grade eight ordinary precision chain". The chain adopts high-quality special steel material fromthe domestic and foreign market and produced in accordance with the standard of GB/T12718-2009. Production range is Φ18-Φ48mm.

Product Usage:

Mine scraper conveyor, scraper loader,plow and other equipment,lifting and is mainly used for machinery manufacture, transportation, mining, etc.

Specifications

| High Tension Round Link Chain For Mining | ||||||||||||

| Diameter of Link d (mm) | Pitch P(t) | Width (mm) | Radius of Arc r(mm) | Diameter at The Weld (mm) | Weight/m (kg/m) | Testing Load (KN) | Min.Breaking Load (KN) | Working Load (KN) | Quality grade | ||

| Minimum Inner Width a | Maximum Extemal Width b | Diameter d1max | Length e | |||||||||

| 18 | 64 | 21 | 60 | 28 | 19.5 | 13 | 6.6 | 260 | 320 | 200 | B | |

| 330 | 410 | 256 | C | |||||||||

| 22 | 86 | 26 | 74 | 34 | 23.5 | 15.5 | 9.5 | 380 | 480 | 300 | B | |

| 490 | 610 | 381 | C | |||||||||

| 24 | 86 | 28 | 79 | 37 | 26 | 17 | 11.6 | 460 | 570 | 356 | B | |

| 580 | 720 | 450 | C | |||||||||

| 26 | 92 | 30 | 86 | 40 | 28 | 18 | 13.7 | 540 | 670 | 418 | B | |

| 680 | 850 | 531 | C | |||||||||

| 30 | 108 | 34 | 98 | 46 | 32.5 | 21 | 18 | 900 | 1130 | 706 | C | |

| 1130 | 1410 | 881 | D | |||||||||

| 34 | 126 | 38 | 109 | 52 | 36.5 | 23.8 | 22.7 | 1160 | 1450 | 906 | C | |

| 1450 | 1810 | 1130 | D | |||||||||

| 38 | 126 | 42 | 121 | 58 | 41 | 27 | 30 | 1450 | 1810 | 1131 | C | |

| 38 | 137 | 42 | 121 | 58 | 41 | 27 | 29 | 1450 | 1810 | 1131 | C | |

| 38 | 146 | 42 | 121 | 58 | 41 | 27 | 27.6 | 1450 | 1810 | 1131 | C | |

| 42 | 146 | 46 | 133 | 64 | 45 | 30 | 36 | 1770 | 2220 | 1388 | C | |

| 42 | 152 | 46 | 133 | 64 | 45 | 30 | 35.3 | 1770 | 2220 | 1388 | C | |

| 48 | 152 | 62 | 163 | 80 | 51 | 34.3 | 45.7 | 2320 | 2900 | 1813 | C | |

| 1. Application area: Mine scraper conveyor, scraper loader,plow and other equipment. | ||||||||||||

| 2. Quality grade: B,C | ||||||||||||

| 3. Marks: Quality grade mark, such as "JLB\JLC". Safety logo “MA”、“KA”. | ||||||||||||

Package

JULI standard export package: Iron drum or Customized packaging according to customer needs

Manufacturing Process

Chain sling factory mainly produce high-tensile lifting chain, high-tensile chain sling, round link chain and steel compact chain for scraper conveyor and auxiliary part for mine chain. Produced in accordance with the standard of EN818-2, GB/T24816-2009, GB/T12718-2009, Q/JL018-2012. Production range is Ф6-Ф48mm.

Export Cases

-Main markets: America, Canada, Mexico, the Middle East, Africa, Australia, Russia, Europe, Japan, Vietnam, India, etc

-Exhibitions:2015.10 KORMARINE, 2016.11 OSEA, 2018.11 OSEA, 2019.11 ADIPEC, 2020.11 Bauma China, 2023.4 Neftegaz, 2024.3 OTC ASIA, 2024.5 OTC America.

FAQ

Q1:Are you factory or business company?

Juli Sling is an OEM&ODM manufacturer with nearly 38 years of history. Focusing on research and development and manufacturing of rigging.

Q2:What is your terms of delivery?

Accept EXW, FOB, CIF, etc. If you have any other choices or requirements, we could negotiate it together to help you find the most convenient and favorable one.

Q3:How does your factory do regarding quality control?

Quality is priority. We always attach great importance to quality controlling. Skillful workers care every details during the production; Strict quality testing in each process; Authoritative testing reports can be provided for customer.

Q4:What payment method is available?

By T/T, L/C, Other methods can be negotiated together.

Catalogue

Download Document

Whether is a product enquiry or technical help, please send messager here, our team will respond within 24-48 hours.