Release time: Jul. 18, 2025

In construction, logistics, shipbuilding, and heavy manufacturing, choosing the right Lifting Sling is critical for safety, efficiency, and equipment longevity. With so many sling types available—ranging from wire rope to chain and webbing—how do you determine which one suits your lifting application? In this article, we focus on Heavy Eye Webbing Slings and what to look for when sourcing from a trusted webbing sling manufacturer like Juli Sling.

A Lifting Sling is a flexible device used to secure, lift, or move loads with a crane or hoist. It distributes the load across a broader surface area, reducing stress on specific lifting points. However, choosing the wrong sling can result in:

Overloading and sling failure

Load imbalance and tipping

Abrasions or damage to sensitive materials

Workplace injuries or equipment damage

That’s why selecting the appropriate material, width, eye type, and rated capacity is essential for every lifting task.

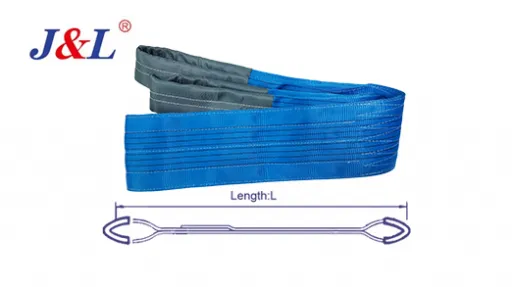

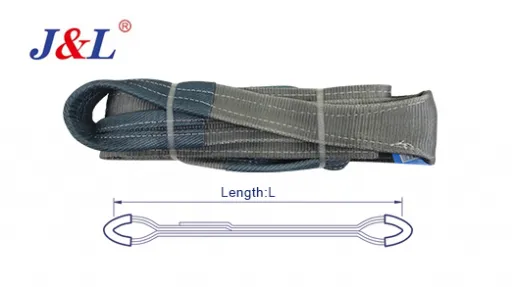

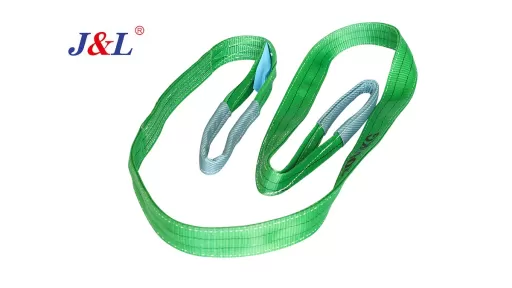

The Heavy Eye Webbing Sling is one of the most versatile and widely used sling types, especially for lifting heavy loads that require durability and flexibility. Made from high-strength polyester or nylon webbing, these slings feature reinforced eye loops on both ends for secure attachment.

Key advantages include:

Lightweight and easy to handle

High tensile strength with shock absorption

Non-damaging to smooth or painted surfaces

Resistant to oil, grease, and mild chemicals

Compact storage and easy inspection

They are particularly suitable for lifting machinery, steel plates, pallets, fragile components, and irregularly shaped loads.

When selecting a sling for heavy-duty applications, consider these points:

Load Weight and Type

Always check the working load limit (WLL) based on the lifting angle and sling configuration (vertical, choker, or basket).

Material Compatibility

Polyester is ideal for acid resistance; nylon performs better with alkalis. Select material based on environmental exposure.

Sling Width and Layers

Wider and multi-layer slings distribute weight more effectively and reduce wear.

Sling End Type

Heavy Eye Webbing Slings offer strong, reinforced looped ends suitable for use with shackles or crane hooks.

Compliance and Certification

Ensure slings are labeled with serial numbers, WLL, and meet EN, ASME, or ISO standards.

As a leading webbing sling manufacturer, Juli Sling offers a full range of lifting slings engineered for industrial-grade performance and certified for global compliance. Advantages of working with Juli Sling include:

High-strength polyester and nylon construction

Heavy Eye Webbing Slings in customizable lengths and widths

Strict quality control and third-party certifications

OEM and private-label options for global distributors

Technical support for load analysis and custom lifting solutions

Whether you’re lifting a 2-ton transformer or a fragile mechanical assembly, Juli Sling ensures that your operations are backed by reliable, certified lifting gear.

W01-8 Eye Type Polyester Webbing Sling

W01-8 Eye Type Polyester Webbing Sling

Compacted Steel Wire Rope

Compacted Steel Wire Rope

Fireproof Eye Round Sling

Fireproof Eye Round Sling

Lifting Chain

Lifting Chain

Hand Pallet Truck

Hand Pallet Truck

High-Tensile Steel Compact Chains For Mining

High-Tensile Steel Compact Chains For Mining

JQS1000 Bridge Erecting Crane

JQS1000 Bridge Erecting Crane

Heavy Eye Webbing Sling W02-08 | Webbing Slings by J&L

Heavy Eye Webbing Sling W02-08 | Webbing Slings by J&L

Protection Type Round Sling

Protection Type Round Sling

Eye Type Webbing Sling

Eye Type Webbing Sling