The product consists of ratchet and belt. You can select ratchet according to your using. The color, material and width of belt, and ratchet are customized.

Description:

Model Number: LS04

Breaking Load: 0.8T-10T

Width: 25mm-100mm

Length: Customized

Safety factor: 2:1 3:1

The material of belt: Polyester, Polypropylene, and Nylon.

Ratchet: Rubber Ratchet, Steel Ratchet, Aluminium Ratchet. Galvanized. Single Lock/ Double Lock.

Hook: Without hook

Standard: Standard EN 12195-2:2000, AS/NZS438, American Standard.

Brand Name: J&L

Place of Origin: Hebei, China

Customized Service: Support customized service. Able to supply different kinds of protecting measures according to different using requirement.

Characteristics: High tension, low elongation, small volume, light weight, easy to operate, safe and convenient to bring.

Usage: Widely used in lashing, tying and even self rescue of trailer during transportation.

Advantage:

Ratchet straps, also known as tie-down straps or cargo straps, are commonly used for securing heavy loads during transportation or for other purposes.

Ratchet straps feature a ratcheting mechanism that allows for tight and secure tensioning of the strap. This mechanism consists of a ratchet buckle and a release lever.

The straps are typically made of durable synthetic materials such as nylon or polyester webbing. These materials provide strength, durability, and resistance to weathering and abrasion.

Juli Sling is a leading supplier of high-quality rigging products with 38 years of experience. As the only CNAS-approved test laboratory in the rigging industry, our Juli Sling Testing Center utilizes advanced electro-hydraulic servo horizontal tensile testing machines to provide comprehensive inspection services for metallic materials, synthetic fiber ropes, and lifting devices. We adhere to rigorous quality management standards, holding numerous certifications including ISO9001, ISO14001, and various international safety certifications. Our diverse product range includes polyester webbing slings, round slings, ratchet straps, steel wire ropes, and rigging equipment, earning us a reputation for reliability and efficiency in the market.

Applications:

Ratchet straps, also known as tie-down straps, are incredibly useful for securing and fastening loads during transportation.

Truck Lashing Straps are fastening devices designed for truck cargo transportation. They are usually made of high-strength materials such as polyester, nylon or polypropylene, and are equipped with fastening mechanisms and hooks (such as D-rings, J-hooks, etc.) to securely fix the cargo in the truck or container.

Specifications

| LS04 Type | Art. No | Breaking Load (kg) | Width (mm) | Total Length (m) | ||

| LS04-008 | 800 | 25 | 6~12 | ||

| LS04-015 | 1500 | 25 | 6~12 | |||

| LS04-02 | 2000 | 35/50 | 6~12 | |||

| LS04-03 | 3000 | 35/50 | 6~12 | |||

| LS04-04 | 4000 | 50 | 6~12 | |||

| LS04-05 | 5000 | 50 | 6~12 | |||

| LS04-08 | 8000 | 75 | 6~12 | |||

| LS04-10 | 10000 | 100 | 6~12 | |||

| Note: End fittings are changeable according to different requirement. | ||||||

| End Fitting | ||

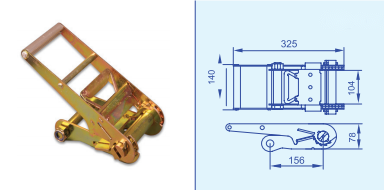

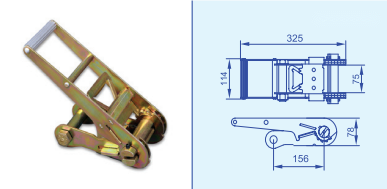

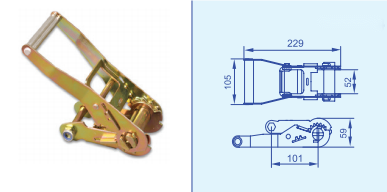

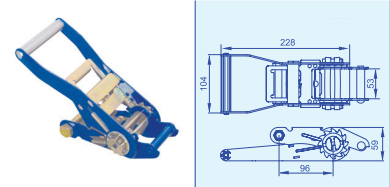

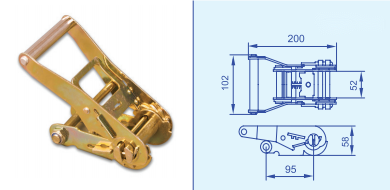

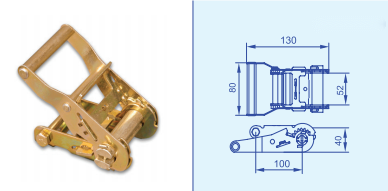

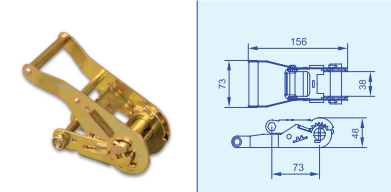

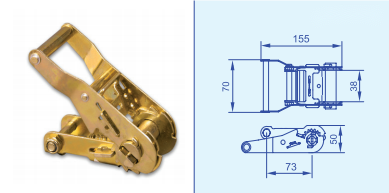

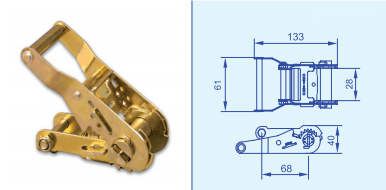

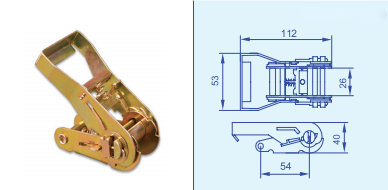

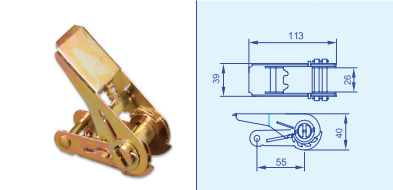

| Ratchet (Unit: mm) | ||

|   |   |

Type: RB001 Type: RB001Size: 4" Breaking Load: 10000 kg Suitable for LS01, LS04 and LS05 ratechet tie down Single Lock Plastic handle/Aluminum handle Galvanized | Type: RB002 Size: 3" Breaking Load: 10000 kg Suitable for LS01, LS04 andLS05 ratechet tie down Single Lock Aluminum handle Galvanized | Type: RB003 Size: 2" Breaking Load: 50000 kg Suitable for LS01 and LS04 ratechet tie down Single Lock Aluminum handle Galvanized |

|  |   |

| Type: RB003-04 Size: 2" Breaking Load: 5000 kg Suitable for LS01, LS04 and LS05 ratechet tie down Double Lock Aluminum handle | Type: RB003-06 Size: 2" Breaking Load: 5000 kg Suitable for LS01 and LS04 ratechet tie down Single Lock/Double Lock Plastic handle/Aluminum handle Galvanized | Type: RB003-07 Size: 2" Breaking Load: 2000 kg Suitable for LS01 and LS04 ratechet tie down Single Lock Steel handle/Aluminum handle Galvanized |

|   |   |

| Type: RB004-01 Size: 1 1/2" Breaking Load: 3000 kg Suitable for LS01 and LS04 ratechet tie down Single Lock/Double Lock Plastic handle/Steel handle | Type: RB004-03 Size: 1 1/2" Breaking Load: 2000 kg Suitable for LS01 and LS04 ratechet tie down Single Lock Steel handle Galvanized | Type: RB005-01 Size: 1 1/16" Breaking Load: 1500 kg Suitable for LS01, LS02 and LS04 ratechet tie down Single Lock Steel handle Galvanized |

|   | -- |

| Type: RB006-01 Size: 1" Breaking Load: 800 kg Suitable for LS01, LS02 and LS04 ratechet tie down Single Lock Steel handle Galvanized | Type: RB006-02 Size: 1" Breaking Load: 800 kg Suitable for LS01, LS02 and LS04 ratechet tie down Single Lock Galvanized | -- |

Customized Packaging

JULI standard export package: Heat shrinking film packaging + Carton + Pallet

Customized packaging according to customer needs

Manufacturing Process

1. Material selection: Ratchet straps are typically made of durable and high-tensile strength materials such as nylon webbing or polyester. The material is chosen for its strength, flexibility, and resistance to weathering and abrasion.

2. Cutting: The selected material is cut into appropriate lengths, usually ranging from a few feet to several meters, based on the desired strap size. Reinforcements or loops are stitched onto one end of the strap to secure hooks or other attachment mechanisms.

3. Ratchet assembly: The ratchet mechanism, which consists of a ratchet buckle and a handle, is assembled separately. The components are typically made of steel or heavy-duty plastic. The ratchet buckle contains teeth that interlock with the strap, providing tension and securing the load.

Production process:Raw Materials—Weaving—Dyeing—Taping—Sewing —Repair and iron—Testing—Packing

Export Cases

-Main markets: America, Canada, Mexico, the Middle East, Africa, Australia, Russia, Europe, Japan, Vietnam, India, etc

-Exhibitions:2015.10 KORMARINE, 2016.11 OSEA, 2018.11 OSEA, 2019.11 ADIPEC, 2020.11 Bauma China, 2023.4 Neftegaz, 2024.3 OTC ASIA, 2024.5 America.

When it comes to securing your cargo during transportation, ratchet straps are a game-changer. Specifically, ratchet tie-downs offer unmatched strength, adjustability, and reliability, making them an indispensable tool for cargo securing needs. At Juli slings, we take pride in manufacturing and supplying high-quality ratchet tie-downs that meet the demands of various industries. Choose our exceptional products and experience the peace of mind that comes with secure and efficient cargo transport. Contact us today to explore our range of ratchet tie-downs and unlock the power of unrivaled quality and performance.

FAQ

Q1:Are you factory or business company?

Juli Sling is an OEM&ODM manufacturer with nearly 38 years of history. Focusing on research and development and manufacturing of rigging.

Q2:What is your terms of delivery?

Accept EXW, FOB, CIF, etc. If you have any other choices or requirements, we could negotiate it together to help you find the most convenient and favorable one.

Q3:How does your factory do regarding quality control?

Quality is priority. We always attach great importance to quality controlling. Skillful workers care every details during the production; Strict quality testing in each process; Authoritative testing reports can be provided for customer.

Q4:What payment method is available?

By T/T, L/C, Other methods can be negotiated together.

Catalogue

Download Document

Whether is a product enquiry or technical help, please send messager here, our team will respond within 24-48 hours.