Release time: Jul. 29, 2025

When it comes to transporting heavy cargo or securing materials during lifting, one factor matters above all: dependable restraint. Standard tie-downs may work for general use, but in demanding environments—construction sites, shipping yards, or industrial transport—Custom Ratchet Straps offer the flexibility and reliability that generic solutions can’t match. At Juli Sling, we manufacture heavy-duty load restraint systems, including lifting slings, metal wire ropes, and custom-designed ratchet straps tailored to meet your specific operational needs.

Unlike off-the-shelf options, Custom Ratchet Straps are engineered for your unique cargo, application, and working environment. From strap length and width to hook type and breaking strength, every component can be specified to match load characteristics and usage frequency. This precision translates into higher safety, faster handling, and longer equipment lifespan.

For example, transporting oversized machinery or fragile cargo often requires unusual anchor points or softer tensioning systems. With custom straps, you avoid the risks associated with makeshift solutions or stretching standard gear beyond its limits.

At Juli Sling, our Custom Ratchet Straps are built with precision stitching, industrial-strength polyester webbing, and corrosion-resistant ratchets to ensure secure and stable hold—regardless of the conditions.

Notable benefits include:

l Tailored length and width to fit odd-shaped or oversized loads

l High Working Load Limits (WLL) for safety under extreme tension

l End-fitting customization, such as S-hooks, flat hooks, or snap hooks

l Weather-resistant materials for outdoor or marine applications

l Color coding and labeling for identification and load classification

These straps are especially effective when paired with lifting sling systems or used in combination with metal wire rope assemblies for high-load or static anchoring requirements.

Custom straps are often used in conjunction with lifting slings, especially in scenarios where the load needs to be both lifted and secured during horizontal movement. In these cases, ratchet straps serve as an added layer of control, reducing sway and maintaining center alignment.

Meanwhile, metal wire rope is the go-to for permanent or semi-permanent securing of extremely heavy loads. But even in these setups, ratchet straps play a role by anchoring supplemental components or acting as backups during tension adjustments or repositioning.

For customers who deal with irregularly shaped loads, construction panels, or high-value cargo, Juli Sling offers custom-engineered packages combining ratchet straps, lifting slings, and metal wire rope components—ensuring safe lifting, secure transport, and full compliance with industry safety standards.

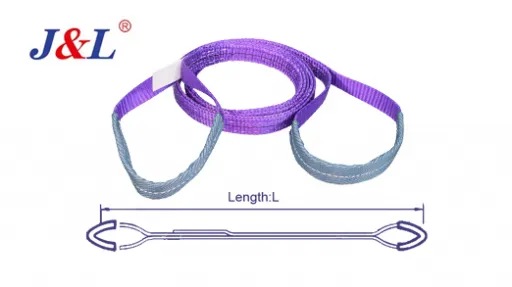

W01-1 Eye Type Polyester Webbing Sling

W01-1 Eye Type Polyester Webbing Sling

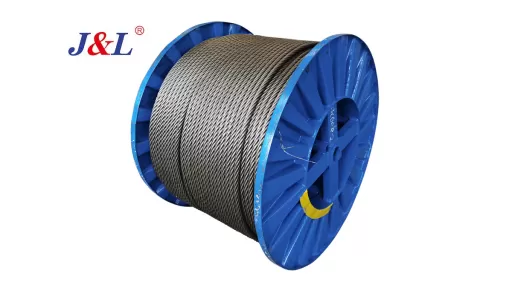

Galvanized Steel Wire Rope

Galvanized Steel Wire Rope

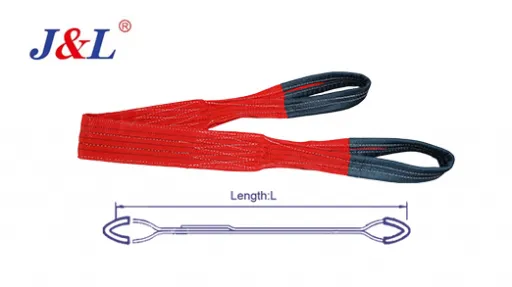

W01-5 Eye Type Polyester Webbing Sling

W01-5 Eye Type Polyester Webbing Sling

PE fiber Mooring Rope

PE fiber Mooring Rope

Lashing Belt Material

Lashing Belt Material

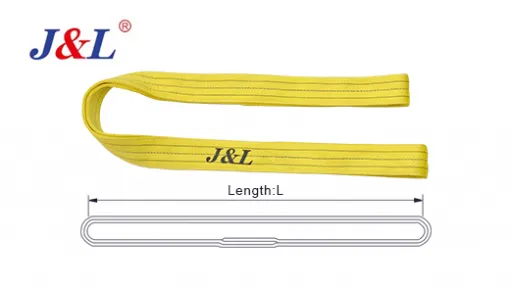

Endless Type Webbing Sling W03-03 | Webbing Slings by Juli Sling

Endless Type Webbing Sling W03-03 | Webbing Slings by Juli Sling

JQSS900 Bridge Erecting Crane

JQSS900 Bridge Erecting Crane

Fireproof Endless Type

Fireproof Endless Type

Vertical Steel Coil Lifting Clamp (Rod grab type)

Vertical Steel Coil Lifting Clamp (Rod grab type)